Plastic is ubiquitous and offers numerous benefits, but improper use and disposal can lead to environmental problems. To reduce the ecological footprint of products starting from the design phase, it is crucial to thoroughly examine the material and consider its recyclability. Using plastic as a monomaterial significantly increases recycling possibilities, supports the circular economy, and helps reduce environmental impacts. To conserve natural resources and reduce carbon footprint, recycling plastic and maximizing reuse is essential.

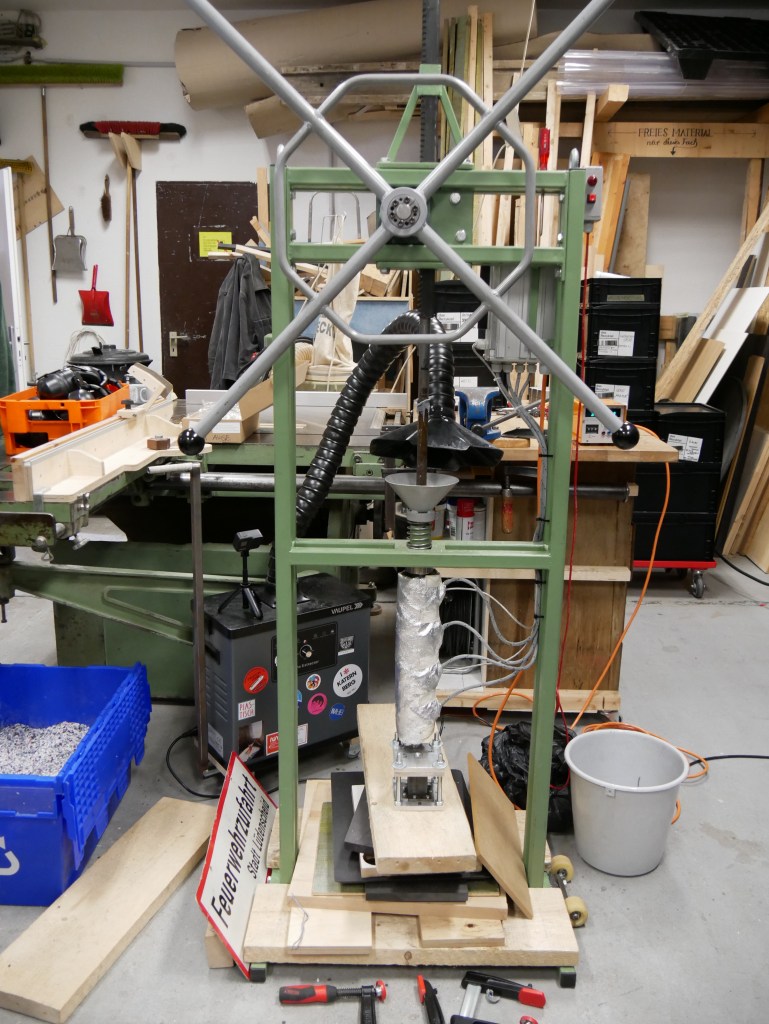

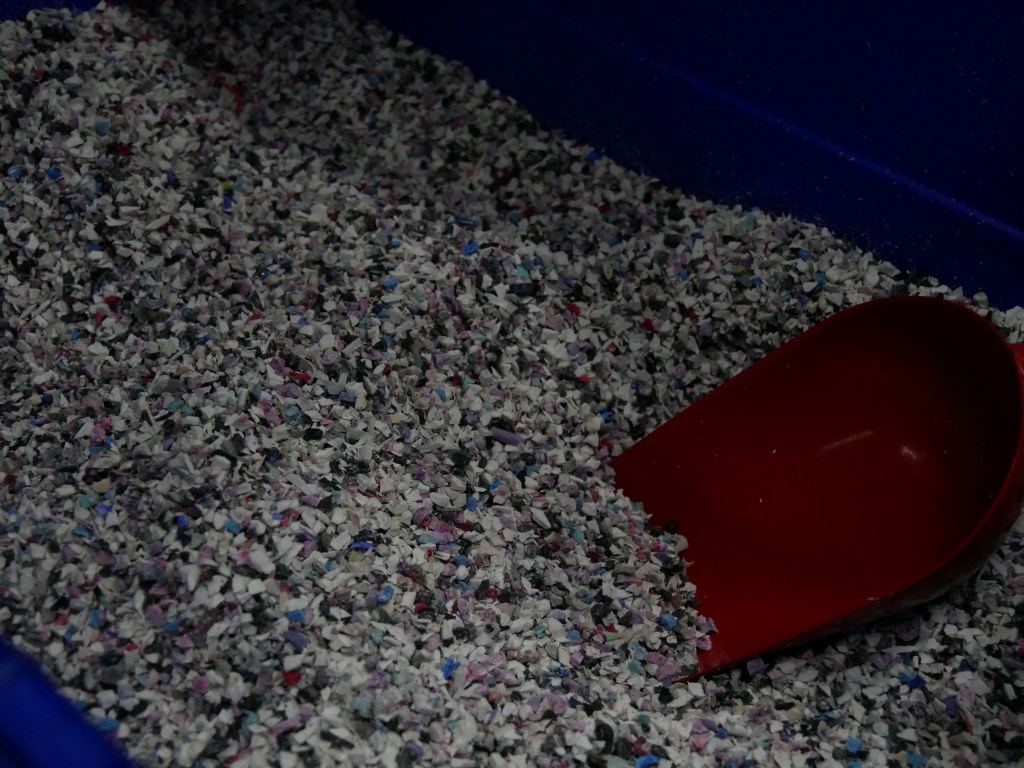

In this project, polypropylene was collected, shredded, and melted in the injection molding machine to reshape it. Through clean separation of polypropylene, it can be recycled, melted, and reshaped repeatedly into new forms.

It is crucial to thoroughly address plastic recycling in the design phase, as plastic waste poses a global environmental issue. Through targeted experimentation, innovative approaches can be discovered to enhance the recyclability of plastic. Injection molding as a manufacturing method offers efficiency and precision in this regard. Utilizing plastic as a monomaterial significantly increases recycling possibilities, promotes the circular economy, and contributes to reducing environmental impacts. This underscores the versatility and positive aspects of plastic when sustainably designed and reused.

The project began with an experiment: The objective was to explore the malleability of hot plastic through experimental methods.

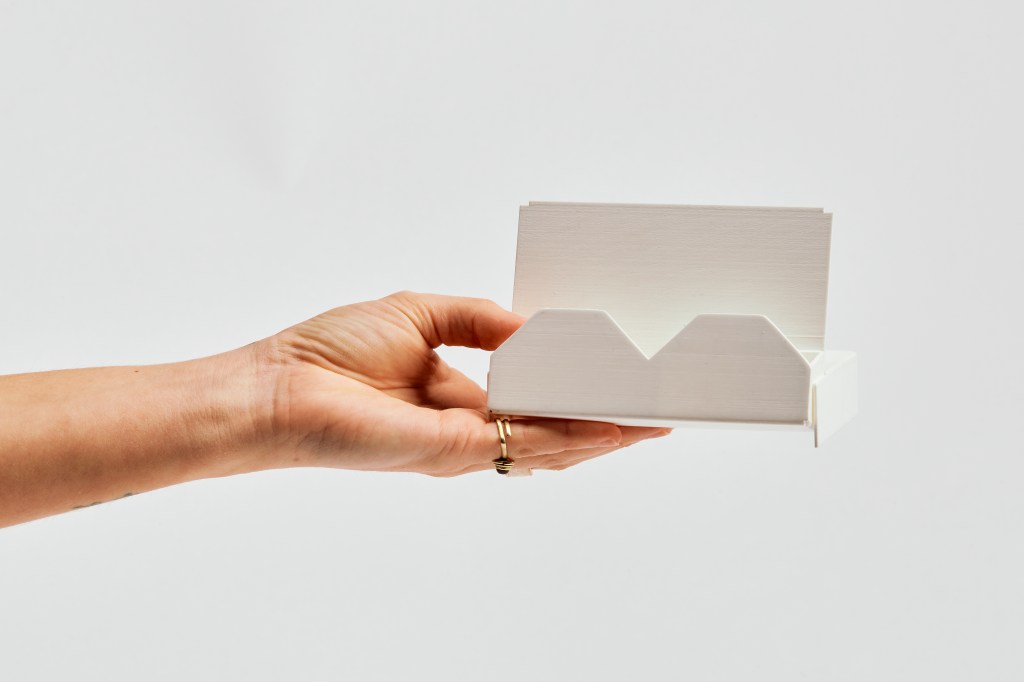

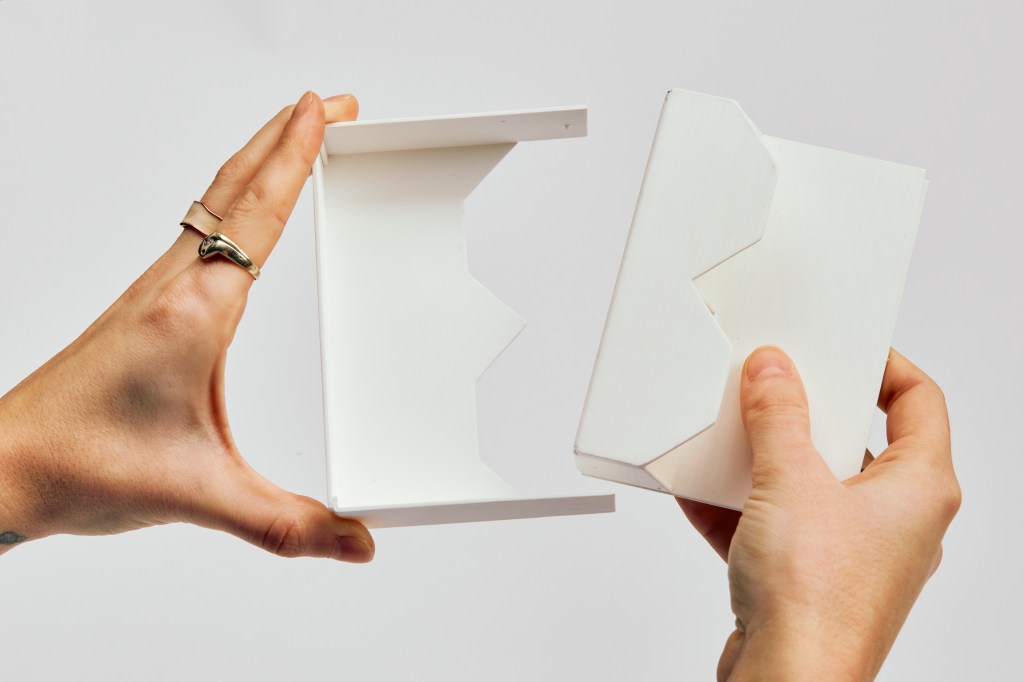

In this project, a mold was created with a focus on folding plastic similar to paper. From this mold, a flat template was derived, which was then laser-cut from recycled plastic. The recycled polypropylene sheet was melted in a hot press using shredded polypropylene to create a nearly uniform sheet. It’s important to note to allow the sheet to cool completely in the press to avoid deformation. Applying heat, the recycled, cut polypropylene sheet was folded, creating a soap box made from recycled polypropylene that can be recycled again and again.

The inspiration for this concept stems from a conscious decision to opt for soap instead of liquid shampoo to reduce packaging waste, with a focus on protecting the soap during transportation.

The recycled PP was melted in a heat press and pressed into a sheet. Subsequently, the PP sheet was cut using a laser cutter.

RE:BOX

RE:Box is a portable soap box crafted from recycled polypropylene. It exemplifies the significance of mono-materials in product design, promoting recycling and reuse initiatives. Its design is inspired by the folding techniques of paper, with meticulous consideration given to the recycling, processing, cutting, and folding properties of polypropylene.

Hinterlasse einen Kommentar